Talking Nanotechnology with David Forrest

David Forrest was one of – if not the very first – to draw attention to the potential for nanotechnology in textiles in a presentation at the Advanced Textiles Association/ATA EXPO (formerly IFAI) in 1995. An MIT graduate, his achievements include an Energy Rock Star Award when working at the Department of Energy, the Assistant Secretary’s 2016 Outstanding Impact Award and the distinguished Career Service Award for pioneering Atomically Precise Manufacturing and covetic nanomaterials. Currently, David is a Principal Technical Consultant with Nexight Group, primarily supporting the U.S. Department of Energy’s (DOE) decarbonization initiatives.

I interviewed David after his very first ATA EXPO presentation, therefore I took the opportunity during the 2023 ATA EXPO to interview him once again to see what progress has been made and what we might expect in the future.

Marie O’Mahony: Let’s begin with a few questions about the technology, can you give your definition of nanotechnology?

David Forrest: Yes, and there is a colorful history of how the definition has changed over the years. In the early 2000s, the ISO working group TC229 on Nanotechnologies debated for over three years before they published the first version of the definition … and they’re still tinkering with it. The short answer is that nanotechnology is the understanding and control of matter at the nanoscale (100 nm or less). But that is so broad that it’s not very useful.

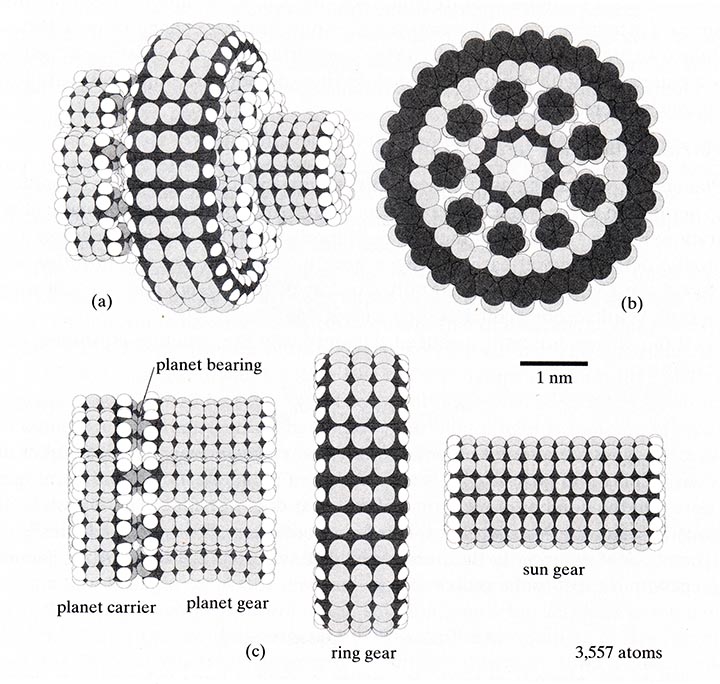

When I was first introduced to the concept in 1985, nanotechnology meant something very different: a technology based on assemblers able to build systems to complex atomic specification under programmable control. Many of us are now referring to this as atomically precise manufacturing, where virtually every atom is placed exactly where you want it to be and there are no defects, missing atoms, or contaminant atoms in the product. So nanomachines were integral to this early definition by Eric Drexler.

O’Mahony: Why is atomic precision so important?

Forrest: Because that extra amount of precision changes the performance of materials by something like a factor of 50. It’s the difference between a full-size car weighing 1300 kilograms vs. only 50 kilos. Atomic precision will make possible clothing that can change its shape and texture in ways that are imagined in today’s science fiction movies but will become tomorrow’s reality. Atomic precision will provide meaning-

ful, economically sensible answers to today’s seemingly intractable problems of pollution of our environment, climate change and destruction of habitats, and human suffering from disease and famine.

O’Mahony: You argue that nanomachines are necessary, can you explain why?

Forrest: Yes, thanks for this question, because it’s the most misunderstood aspect: You can’t mass-produce by pushing atoms around with a microscope. And that was never the claim. There’s also been a lot of nanotech funding of nanoparticles, but you’ll never make anything like these strong, shape-changing textiles with nanoparticles. One can make atomically precise thin membranes at commercial scale – and that’s been an important breakthrough – but if you want to make cars and laptops and skyscrapers to atomic precision you need nanofactories with assembly lines that have trillions of molecular machines. That’s how life on earth works, too, by the way. Our biosphere grows and is sustained by vast numbers of molecular machines.

O’Mahony: We are doing this interview at the ATA EXPO 2023 where you are speaking 28 years after your first seminal paper presenting nanotechnology to the textiles industry. I have to ask – what happened to the little black dress that would morph from office attire to evening wear? I was so looking forward to it!

Forrest: Those molecular machines can’t come soon enough, Marie.

O’Mahony: One of the big controversies in textiles right now revolves around “forever chemicals,” with many calling for an outright ban on chemicals such as PFAS. Do you see a role for nanotechnology here as it is already in widespread use in textile coatings and finishes?

Forrest: When you can make textiles atom by atom, molecule by molecule, from the bottom up, there won’t be any need for these toxic chemicals in the production process. In the meantime, atomically precise membranes will have the ability to screen out these sorts of chemicals so there’s a near term solution looming to clean up our water.

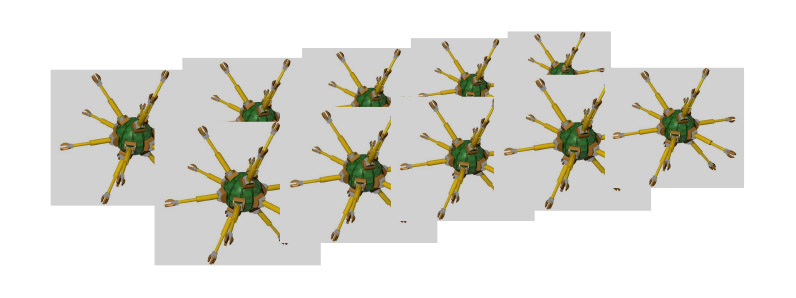

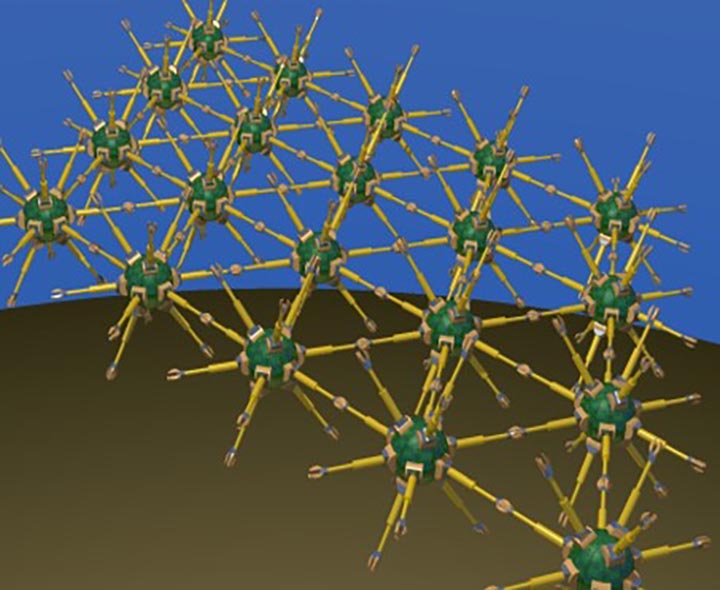

O’Mahony: What is a utility fog?

Forrest: It’s a great idea for a “material” that’s part machine, part computer, and part scaffolding … blurring the distinction between all three. Microscopic nodes with computers and motors and telescoping arms are linked in a vast three-dimensional array with data signals and electrical power being transmitted from one to the next. As the arms expand and contract the entire structure changes shape and size in a programmed way. That’s the basis for the material for that little black dress you want.

O’Mahony: It sounds like the utility fog might offer some unique possibilities for responsive materials such as smart materials wearables and medical devices. Would you care to speculate on this?

Forrest: Well, it could be just be a single object like a chair that resizes and reshapes itself to be distinctly comfortable to whoever sits on it. Or the sole of a shoe that supports the contours of your feet perfectly. Josh Hall, who’s written about this extensively, imagined being surrounded by this fog of machines that could condense useful objects all around you on command – seemingly from thin air. Or serve to protect people from impacts and flying debris, kind of like a personal shield.

Back in the year 2000, I moderated a panel of nanotechnology experts at a conference, and I became haunted for a long time by a comment from Rod Ruoff. We were all talking about diamond being the future material of choice due to its low density and fantastic strength and he said, ‘Look, diamond is incredibly strong, but in order to take advantage of that strength you have to strain it 10% and I don’t know how to do mechanical design with that much strain.’ He was right, of course, and I didn’t have an answer until years later when I realized that utility fog solves this problem: the telescoping arms can compensate for the high levels of strain. As forces on the system pull and strain the diamond arms like rubber bands, motors contract the arms to keep the distance between nodes constant. The shape doesn’t change despite extraordinary forces.

O’Mahony: You have talked about an actuating motion of large objects created by broadcasting signals to a networked array of millions of atomically precise molecular machines. Do you envisage this as something that happens locally, say close to the body, or might it be across larger distances such as networked vehicles?

Forrest: I chose that language to equally describe the way muscles work in people, or the way nanomachines could work in (for example) a car that could morph from having a sports car body to an SUV on command. It’s always a challenge to describe a world filled with future nanomachines in familiar terms, and it’s helpful to have biological examples (like muscles) as existence proofs. You’re way ahead of me on the networked vehicle idea! That could very well solve things like multi-car pile-ups on the highway if the vehicles were coordinated with each other.

O’Mahony: New materials and functions, environmental benefits, all marvelous. What does this mean for manufacturers? Are we talking imminent scalability, working within existing factories or is it a whole new set of tools and machines?

Forrest: This is interesting, right? If you have a desktop factory that can make atomically precise products from a few bottles of basic chemicals, then why do you need to make things in centralized factories halfway around the world?

Of course, it’s going to take awhile to advance the technology to the point of desktop factories, but we’re talking about a few decades from now, not hundreds of years. For now, manufacturers can rest easy. Someday, “manufacturing” may mean sending a software instruction set to somebody’s desktop nanofactory for on-site production of a shapeshifting little black dress.

O’Mahony: There is a trajectory in new materials and technology when first introduced they look to mimic existing materials before moving on to produce novel materials. Would you agree with this and if so, can you offer an idea that you would like to see nanotechnology evolve?

Forrest: I definitely agree with your observation, Marie. One of my favorite examples is the idea that was developed by a small company named Covalent, which based the design for an atomically precise membrane on a cellular structure called an aquaporin. If they get to commercialization, it will be game-changing for reducing the operating costs of desalination plants.

O’Mahony: The initial vision for nanotechnology was of molecular gears and bearings and motors and mechanical nanocomputers. Is that still on the horizon?

Forrest: We can’t scale up production without these sorts of machines, so the answer is “Yes” for sure. I’m happy to report that the first examples of these devices are now in the rearview mirror: Nanocar races compete different designs against each other, and the electric motor powering the nanocars won a Nobel prize in 2016 for its inventor, Prof. Ben Feringa.

O’Mahony: David, it has been a pleasure as always. Final question: If we were to talk again in ten years, what would be the one thing that you would like to be able to point to and say ‘Nanotechnology did this’?

Forrest: Atomically precise membranes. Because they could be used for cleaning toxins from water, cleaning blood to eliminate kidney dialysis, mining valuable minerals from seawater, and cheaply removing greenhouse gases from the atmosphere.