In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: January 19, 2024

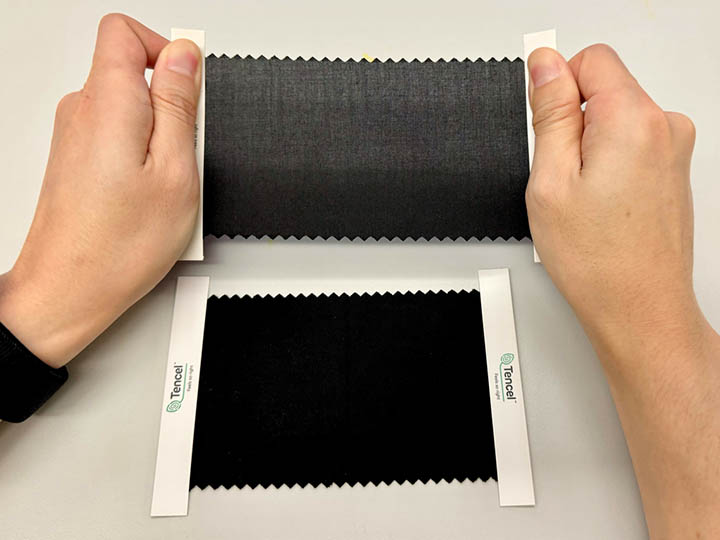

TENCEL Lyocell Fibers as Alternative Material for Stretch Fabrics

Lenzing Group, a leading global producer of wood-based specialty fibers, announced a new processing technique of TENCEL™ branded lyocell fibers tailored to create stretch fabrics that enhances comfort of the wearer. This solution offers a fossil-free alternative that delivers exceptional stretch and recovery properties while adhering to responsible production methods.

Lenzing’s new processing technique involves re-engineering woven fabric composed of TENCEL™ Lyocell fibers coupled with a fabric pre-treatment. During the wet process, TENCEL™ Lyocell fibers undergo significant swelling in diameter, leading to increased yarn crimps in the widthwise direction. This translates into a fabric that can stretch with enhanced recovery and does not shrink or wrinkle easily, maintaining a smooth appearance even after home laundering.

To take a step further, Lenzing extends its comprehensive support at the fabric development level to mill partners. The stretch fabrics made using TENCEL™ Lyocell fibers meet the international standard for fabric stretch and recovery properties. The collaboration with Lenzing will enable mills and brands to unleash unlimited design possibilities while addressing the growing consumer demand for comfortable apparel produced responsibly, particularly in sectors such as sportswear, athleisure garments, loungewear, and home textiles.

Call for WOW Papers

INDA announced a Call for Presentations for the 2024 World of Wipes® International Conference. World of Wipes (WOW) is organized and presented to the nonwoven fabrics industry by INDA, Association of the Nonwoven Fabrics Industry. Presentations at WOW will focus on a series of market and technical topics (listed below) to provide opportunities for industry leaders to review the latest research, product innovation, and market applications for all wiping products and their components. WOW will target end use wipe manufacturers, converters, and their suppliers.

The call for Presentations are for the following key themes:

- Dry and wet wipes

- Circular economy

- Sustainability / End-of-life implications

- Substrate formation

- Skin care formulations

- Raw materials

- Packaging

- Machinery and equipment

- Market trends and consumer insight

- Regulations

- Ecommerce / Retail channels

The deadline for submitting papers is Friday, January 26, 2024. The conference takes place June 17-20, 2024, at Hyatt Regency Minneapolis, Minneapolis, Minnesota.

Beaver Announces Mexico Expansion

Beaver Manufacturing Co., a global leader in the finishing and processing of high-quality technical fibers, announced a major expansion of its production facility in Tepeji del Rio, Mexico. The plant will be expanded by 67,000 square feet, more than double its existing size of 55,000 square feet.

For the expansion, Beaver is taking over and renovating a vacated space adjacent to its current facility, which it opened in June 2018. In addition to renovating the space to meet the needs of the production, the company will be investing in new equipment for its twisting and treating production. The upgraded facility will be operational by the end of the first quarter of 2024.

“This expansion is necessary to continue to service and grow our business in Mexico and South America, as well as supporting our U.S. business,” said Mike Dubin, President & CEO, Beaver Manufacturing Co. “With this move, we are excited for the opportunity to surpass our customers’ requirements and expectations.”

Beaver will be adding 33 percent more capacity to its fiber-twisting production and the company will install new state-of-the-art equipment for its BEAVERLOC® and RFL treating technologies.

FILTECH 2024: Call for Papers

The world’s largest filtration event, FILTECH, has issued a call for papers for the conference scheduled for November 12-14, 2024, in Cologne, Germany.

The FILTECH 2024 Conference will feature the latest advances and techniques in liquid/solid and gas/particle separation (dust, gas & air filtration) during three days of in-depth exposure. Technology and know-how transfer is a main target.

Industry professionals are invited to present their latest research at the conference to an international audience and network with filtration experts from all over the world. Deadline for submitting abstract is May 31, 2024. More than 200 presentations are planned for the event. Topics copvered are:

- Solid-Liquid-Separation

- Solid-Gas-Separation

- Filter Media

- Testing; Instrumentation; Control

- Simulation and Modeling

- Product Related Processes

- Membrane Processes.

Trojan Technologies to Sell Salsnes Filter Business

Trojan Technologies announced their plan to sell the Salsnes Filter business to current and former members of the Salsnes management team, with an anticipated closing of the transaction in mid-January 2024. Following the closing, Salsnes Filter will be a standalone organization and no longer an affiliate of Trojan Technologies.

The transaction will provide Salsnes-Filter with the opportunity to reinvest further in their solids separation filter technology to better serve the demands of the water treatment industry.

Since 1991, Salsnes has been offering their solids separation filter technology and pursuing research, product development, testing, and quality initiatives. This focus and dedication have produced a highly efficient and reliable filter that maximizes solids separation, while dramatically decreasing costs including capital, operating, maintenance and land. With installations around the world and in a variety of municipal and industrial applications, the Salsnes Filter system is synonymous with eco-efficient solids separation technology. Salsnes Filter will remain at its current production facility in Salsnes Norway.

Atlas Copco Names New CEO

Atlas Copco has named Vagner Rego new president and CEO, effective May 1, 2024. He will replace Mats Rahmström who has requested to leave his position after leading the Group since 2017.

Rego, currently senior executive vice president and president of the Compressor Technique business area, joined the Group in 1996 as a trainee engineer in his native country Brazil. A decade later he was appointed Business Line manager for Compressor Technique Service in Brazil and in 2010, he became vice president of Marketing and Sales for the Compressor Technique Service division, based in Belgium. He has also been general manager for Power Technique’s Customer Center in Brazil. Before he took on his current position in 2017, he was president for the Compressor Technique Service division.

Rego has a degree in mechanical engineering from Mackenzie University and an MBA from Ibmec Business School, both located in Brazil. Rego will be based in Stockholm, Sweden.

JEC Reveals Innovation Awards 2024 Finalists

JEC Group has revealed the finalists for the coveted JEC Innovation Awards 2004. The award, which is to be announced later this winter, has 33 finalists for 11 categories. They are:

Aerospace – Parts

Fuko srl (Italy)

ATG Europe (Netherlands)

Sogeclair Equipment (France)

Aerospace – Process

Spirit AeroSystems (USA)

German Aerospace Center (Germany)

AIRBUS DS – Defence & Space (Spain)

Automotive & Road Transportation –Parts

Toyota Motor Corporation (Japan)

Center for Composite Materials – University of Delaware (USA)

Voith Composites SE & Co. KG (Germany)

Automotive & Road Transportation – Process

Weav3D (USA)

Teijin Automotive Technologies (France)

Röchling Automotive SE (Germany)

Building & Civil Engineering

Armacell Benelux S.C.S. (Belgium)

RENCO USA (USA)

FibR GmbH (Germany)

Circularity & Recycling

FAIRMAT (France)

GREENBOATS GmbH (Germany)

B&M Longworth (Edgworth) Ltd (UK)

Digital, AI & Data

Plataine (Israel)

CTC GmbH (Germany)

ReliaBlade (Denmark)

Equipment, Machinery & Heavy Industries

Synthesites (Greece)

AgriLight – Research Group (Germany)

DIFT (Germany)

Maritime Transportation & Shipbuilding

Gurit (Switzerland)

AYRO (France)

Paul Dijkstra Composites (Netherlands)

Renewable Energies

Vestas Wind Systems A/S (Denmark)

ACCIONA CONSTRUCTION S.A (Spain)

Tree Composites (Netherlands)

Sports, Leisure & Recreation

Radiate Engineering & Design AG (Switzerland)

silbaerg GmbH (Germany)

Helicoid Industries (USA)

American Flock Association Launches Flock 4.0

The American Flock Association (AFA), which represents flock manufacturers and their suppliers In North America, formally introduced a new website, logo and tagline in connection with the launch of Flock 4.0, a program designed to highlight the many innovative ways that North American flocking manufacturers are using flock to add value to a new generation of high-tech products.

The rebranding of the AFA through Flock 4.0 underscores an evolution in this industry that has been underway for the past decade. Historically, flock has been seen as a design element that can enhance the appearance and hand of consumer goods. Flock 4.0 underscores the fact that Flocking can do – and is doing – much more. This includes, but is not limited to, using flock in new electric vehicles to reduce sound, rattles, echoes and windshield glare. Flocking is also applied to boats to improve speed and save fuel. It can also be used as a thermal isolator or added to car floor mats to add slip resistance.

Ambic, Fujicor Becomes F&A Nonwovens

Japanese Nikke company announced that the two subsidiaries Ambic Corporation and Fujicor, Inc., have merged, creating a new company, F&A Nonwovens. Both companies were integrated manufacturers of nonwoven fabrics and felts supplying products to a wide range of industries including environmental, automotive and office automation. Integrating the two businesses is expected to achieve efficiency and concentrate of the management resources of both companies.

ACG Nyström Reports Solid Success in Embroidery Machine Sales

Swedish company ACG Nyström reported solid sales of its embroidery machines with the latest Tajima TMEZ models in Scandinavia, and, surprisingly, in Ukraine. The Tajima TMEZ range of single and multi-head embroidery machines is rapidly introducing intelligent thread management (I-TM) to the market, enabling virtually anyone to quickly and easily become an embroidery specialist. The TMEZ machines are fully enabled for ease of operation by Tajima DG by Pulse – the strongest embroidery software on the market.

Despite Russia’s ongoing assault on its country, ACG Nyström Ukraine, which was founded in 2005 and is based in Lviv, 70 kilometers from the Polish border, reports that its customers are currently extremely active, and a number of new embroidery machines have been installed in the west of the country over the past year.

“Some of our customers have also been forced to leave their businesses in the east of the country and have now successfully relocated in the west, where it is relatively calm, although we are still very scared,” said ACG Nyström Ukraine managing director Halya Andrushkiv. “Keeping busy also helps to keep everybody’s minds off the situation here.”

While military badges have been one growth area, there also remains much activity in branded corporate apparel and there has meanwhile been a huge revival of interest in vyshyvankas – the elaborately embroidered shirts and dresses traditionally worn in the country.

Shelton Vision Pushes Needle on AI Quality Control

Having successfully demonstrated its WebSpector automated fabric inspection system detecting faults on camouflage fabrics at speeds of up to 100 meters a minute during ITMA 2023, British Textile Machinery Association member Shelton Vision has secured an unprecedented number of new orders in many fields of the textile industry.

“We are definitely seeing a ‘sea change’ across the textile industry, with a new generation of management rapidly embracing imaging technology and fully automated fabric inspection,” said Shelton Vision CEO and Managing Director Mark Shelton. “On top of all the throughput and first quality yield improvement benefits our automated fabric inspection can bring, companies throughout the industry, face difficulties in recruiting, training and retaining staff, especially those needed to carry out repetitive manual fabric inspection.”

At best, he adds, studies show that manual inspection can detect around 65% of faults present in the fabric, while the WebSpector offers automated defect detection of over 98%.

“Not only this, using machine learning, the vision system automatically trains new styles, and our AI platform is continuously updating to achieve high accuracy of real time defect naming and grading to eliminate false positives and provide consistently accurate data for both roll cutting optimization and yield increase, as well as for optimizing fabric utilization in panel cutting processes,” he said.

ProTact by Haartz™ Line Expands its Offerings

The Haartz Corporation, a global leader in highly engineered and uniquely designed textile materials, announced that its ProTact by Haartz™ material is now available in MultiCam® patterns. MultiCam® is an original combat-proven pattern officially issued for use by the US Army for its Afghanistan operations in 2010 and remains a leading name in concealment pattern solutions.

The different camouflages from MultiCam® incorporate unique high-resolution patterns designed using tests that studied how camouflage works in nature to increase its wearer’s concealment properties. Variants can be applied to printed textile applications across different global environments, elevations and light conditions.

ProTact by Haartz is a multi-layer textile laminated material that provides military, law enforcement, SWAT teams and other first responders with a durable material tested against flex and fatigue, fabric fraying, high-temperature laundering and high-temperature and humidity endurance. The design of ProTact material is adaptable and can conform to a wide range of patterns including each MultiCam® variant and can be scaled to meet growing demand.

Sunbrella® Launches Home Goods Made From Upcycled Sunbrella Fabrics

Sunbrella® has announced the launch of Sunbrella ReMade™, a new offering of thoughtfully designed home goods made from upcycled Sunbrella fabrics.

The artisanal offering ranges from tabletop accessories to tote bags, wall hangings and more. These products deliver the performance, durability and cleanability of Sunbrella while reducing waste and upcycling materials into the brand’s first circular finished product offering.

“While we have long prioritized sustainable practices, Sunbrella ReMade represents a new extension of our commitment to sustainability as we look to further connect our design team’s expertise to the circular economy,” said Allen Gant III, general manager of lifestyle products at Sunbrella. “Finished home goods made from repurposed industry-leading performance fabrics were missing in the marketplace and we’re glad to give consumers another option where performance, sustainability and elevated design can coexist without compromise.”

Sunbrella ReMade goods utilize excess fabrics from the brand’s design and manufacturing process, including sample sets, design trials, short rolls and other sources. The fabric is upcycled into thoughtfully designed one-of-a-kind coasters, placemats, table runners, aprons, tote bags and wall hangings that can double as picnic blankets.

Duvaltex Announces Intention to Restructure Operations

Duvaltex, a global leader in Contract Textiles and Protective Textiles, and a pioneer in sustainable textiles, announced in December that it has sought protection under the Companies’ Creditors Arrangement Act (CCAA) before the Superior Court of Québec, Canada, in order to provide the Company with time to restructure its finances, while continuing normal operations. The Company has initiated a corresponding filing in the United States under Chapter 15 to recognize and give effect to the Canadian filing.

Duvaltex continues to face repercussions of the COVID-19 pandemic on its sales, particularly in the contract textile segment. The decline in sales and profitability, coupled with the accumulated debt from acquisitions and consolidation initiatives, has put the Company in a challenging financial situation.

By undertaking a restructuring process under the CCAA, Duvaltex will be able to ensure that there are no business interruptions and that deliveries continue as planned. This process gives the Company the necessary protection of the Court to negotiate current and future financial obligations, while continuing to execute its strategy to drive profitable growth.