Global life expectancy has risen to 71.7 years in 2022 (from 64.5 years in 1950) and is set to rise further to 77.3 years by 2050 according to figures from the United Nations Population Division. Access to healthcare and medical advances are key contributing factors with countries spending most on healthcare tending to have higher life expectancies up to 80 years of age. It is worth noting that an exception here is the United States that has the largest spending but a lower life expectancy than many countries spending less.

Textiles play an important role in all aspects of healthcare and this is reflected in the global medical textiles market that is expected to grow at a CAGR of 5.92% between 2023 and 2027 according to Research and Markets, while a separate report by Markets and Markets anticipate that the biomedical textile market alone will reach $20.7 billion by 2027, growing at a CAGR of 6.3%. Fiber, foam and fabric developments are becoming increasingly smart with functionalities that range from sensing and data communication to pain relief and repair. This article looks at three examples of these developments, looking at what they do and why, but also focusing on some of the novel ways that they are using and combining different process including Flexible Hybrid Electronics (FHE), smart yarn and liquid metal foam sensors.

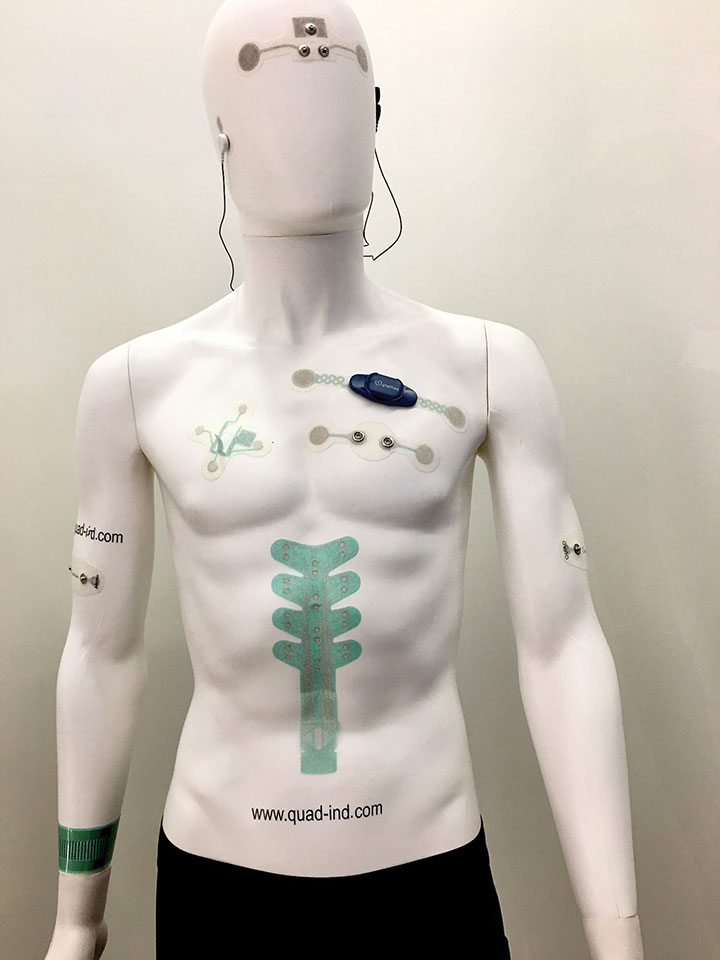

Flexible Hybrid Electronics (FHE) is an area of growing importance for both smart (including medical) textiles and the electronics industries. They allow for a greater integration of electronics and textiles with the benefit of flexibility, stretchable and conformable. The functionalities they offer include heating, sensing, data gathering and communication, lighting and pain relief. Medical skin patches allow for untethered monitoring of different vital signals such as the heart, using Electrocardiogram (ECG), brain, using Electroencephalogram (EEG), and muscle, using Electromyography (EMG). Quad Industries manufacture electronic skin patches and diagnostic electrodes that are well suited for remote and long-term monitoring of ECG, EEG, EMG and emotional state using Galvanic Skin Response (GSR) measurements. In addition to monitoring and measurement, electrostimulation can also be incorporated into the patch. Although very slim and flexible, the patch is comprised of multiple layers. Innermost is a sensor dot cradle and snap button, then a textile layer of medical-grade nonwoven followed by a low temperature hotmelt with ultrathin, flexible and stretch thermoplastic polyurethane (TPU) followed by a stretchable conductive silver then dielectric and silver chloride inks. Skin adhesives with hydrogel or dry electrodes are next to the skin with these determined by the use-case and protected by the release liner prior to use. Dry electrode adhesives offer the possibility of wearing the patch for several days, particularly important when dealing with patients with fragile or sensitive skin.

Quad has collaborated with Mentech to apply their technology to a smart sock designed to monitor stress levels in patients who cannot easily express their emotions. Regular wrist monitoring does not work effectively for people with dementia for example, and they are prone to removing or damaging the device. The sock uses an Electrodermal Activity (EDA) sensor with measurements taken by two electrodes connected to two sensor pads placed on the sole of the foot, the area that researchers have found best to measure skin conductivity. A meandering print is used to allow for the stretch needed and avoid damaging the electrodes. A HUME-module is located above the ankle to collect and analyze data and send it via Bluetooth to a device such as a smartphone. The smart sock offers a number of benefits over patches, including the ability to monitor unobtrusively using a familiar piece of clothing, the ability to reuse and its washability.

Smart yarns are being developed that offer an array of functions from monitoring to active healing. These are increasingly fine, offering a more fully contained system significantly reducing, or even eliminating altogether, the need for additional components that add bulk and reduce flexibility and comfort. In a smart yarn development from Volt, part of the Supreme Corporation, nanotechnology and photomedicine technologies combine to improve the healing speed and process of a wound or infection. The company has worked with the Advanced Functional Fabrics of America (AFFOA) to develop a TTS- Nano-Hybrid LED yarn that uses an AFFOA monofilament embedded with tiny LEDs. Multifunctional nano platform technologies are used to provide theranostic functionalities that pair diagnostic biomarkers with therapeutic agents. A key component is the ability of visible light to activate particular dye molecules to perform certain functionalities.

Principal Scientist Rakkiyappan Chandra describes the impact of the three different types or infrared radiation on the skin with the shortest wavelength, Near-infrared (NIR) capable of penetrating the skin’s epidermis layer to remove toxins, stimulate skin renewal and tissue growth. Mid-infrared (MIR) is a longer wavelength that can penetrate deeper into the body’s soft tissue where inflammation can occur, there it helps to expand the blood vessels, increasing circulation so that oxygen can reach the injured area and also stimulate the cardiovascular system. The longest wavelength is Far-infrared (FIR), capable of penetrating deep into the body where toxins are stored, using heat to stimulate sweat glands and expel heavy metals and other toxins. The skin has been shown to be an excellent IR emitter, with textiles found to offer low IR transparency and capable of strongly absorbing human body radiation.

Photodynamic Therapy (PDT) dates back to 1900, discovered by Oscar Raab who showed that exposure to light resulted in microorganisms being killed. The difference between many of the therapies already in existence is that this does not need an external light source, usually only available under controlled conditions in a hospital. The TTS yarn operates by harvesting and converting the body’s own heat energy, reflecting it back to the body as light energy. The yarn can be used in medical bandages as well as base-layer garments, socks and gloves forming a Thermoregulating Therapeutic Smart Fabric (TTSF).

Liquid metals (LMs) are attracting attention as a form of soft electronics with good stretch, deformation and durability. Researchers at North Carolina State University and universities in China are developing it as a soft stress sensor. They have outlined their research in a recent paper titled “Breathable encapsulated liquid metal foam-based soft stress sensor” published in Advanced Materials Technologies. “Liquid metals” is the term used to describe liquids that are at or near room temperature. With properties of non-toxicity, they offer high electrical and thermal conductivity. They can be produced as a soft stress sensor either by injecting the LM info an elastomer, mixing the particles with elastomers or depositing the material on a flexible substrate such as a fabric or elastomer. It works when stress is applied causing deformation in the geometry changing the conductive paths and resistance allowing the stress to be measured.

There can be an issue around wearer comfort and breathability as the LM is encapsulated in an elastomer that can cause skin irritation. To overcome this problem, researchers have been developing a breathable encapsulated LM foam (BELMF)-based soft stress sensor. Additional to this is a three-dimensional electrode designed to implement the electrical connection without any decrease in breathability. Hollow polydimethysiloxane (PDMS) foam has a porous structure and is comprised of three layers with the middle layer containing the liquid metal, sandwiched between upper and lower layers of a regular PDMS foam used to avoid smearing of the LM while maintaining breathability of the BELMF.

The process used is a lost paraffin method used to eliminate the risk of delamination. The 3D electrodes are made of a three-branched copper wire as a metal foil option would not be air or sweat permeable. The fork-like configuration is used to make it easier to insert into the foam. The LM foam (BELMF)-based sensor is intended for applications in human health monitoring. Sweat tests have been undertaken attaching the samples to the skin using breathable bandages and assessed after the wearer has completed 15 minutes of exercise. Despite perspiration no contact was found to have been lost. Initial tests have been conducted in the bending of the wrist, elbow, knee and neck with positive results. The sensors can also be used to measure the motion of the face and foot, suggesting applications there also.

While the last sixty years have seen a significant increase in global life expectancy, the WHO estimates that chronic diseases are responsible for 71% of deaths each year. Even without succumbing to a life-threatening illness, the average person is described as living their lives in health that is described as being “less than good.” These are significant figures that will continue to motivate the research and development of medical textiles that are smart and designed to be worn comfortably over extended periods of time.