In the dynamic and global textile fiber industry with its various manufacturing processes and end-uses, news and information is breaking on a daily basis. International Fiber Journal is tracking stories relevant to our industry from manmade to natural to bio-based fibers, innovations in nonwoven, woven, braided and technical textiles, technologies for additives, bonding, coatings and polymers, and applications from apparel to hygiene to transportation, and more. Here we will post news stories relevant to textile fibers and their downstream applications on an ongoing basis. Please check back for regular updates. If you have news that you feel should be added to this summary report, please email it to Ken Norberg at ken@ifj.com.

Most recent update: June 23, 2023

Program Announced for RISE® 2023 – Research, Innovation & Science for Engineered Fabrics

The theme for the 13th edition of RISE® (Research, Innovation & Science for Engineered Fabrics) is “A New Era in Manufacturing for Sustainability.” Technology scouts, product managers, senior scientists, development engineers, and business developers will convene September 26-27 at North Carolina State University and The Nonwovens Institute in Raleigh, NC to discover the latest nonwoven innovations.

The RISE conference program features industry leaders from these companies: American Truetzschler, Berry Global, Dilo Incorporated, Evonik Corporation, Indorama Ventures USA, MANN+HUMMEL, the National Renewable Energy Laboratory, NatureWorks, The Nonwovens Institute, Owens Corning, PCI Wood Mackenzie, PolyQuest, Reifenhäuser REICOFIL GmbH, and Simplifyber. These industry experts will discuss the future of nonwoven manufacturing, advances in filter media, rPolymer developments, and sustainable applications.

Innovations that advance the nonwovens industry will be recognized with the 2023 RISE® Innovation Award. Three finalists will present their innovative products or technologies to RISE participants, Tuesday, September 26th. Nominations for the award are being accepted through June 19th. The 2022 award winner was DiaperRecycle, cat litter made from recycled diapers.

RISE participants have the option of touring The Nonwovens Institute’s $65 million-plus, 60,000 square-foot facilities featuring state-of-the-art equipment, pilot lines, and analytical laboratories, as well as attending an evening reception at the Lonnie Pool Golf Course Clubhouse. During the evening reception, graduate students and faculty from North Carolina State University will feature their research and technical advances with poster presentations. The tour and reception will take place Tuesday, September 26th and the tour is limited to 40 attendees. An RSVP is required.

INDA Receives United Nations Accreditation; Participates in Plastics Treaty Negotiations

INDA, the Association of the Nonwoven Fabrics Industry, was granted status last month as an accredited stakeholder with the United Nations Environment Programme (UNEP), which, among other privileges, will allow representatives from the association to observe the formal ongoing negotiations of the UN Global Plastics Treaty.

INDA Government Affairs Director Wes Fisher was on site at the second session of the treaty negotiations formally titled the “second session of the Intergovernmental Negotiating Committee to develop an international legally binding instrument on plastic pollution, including in the marine environment.” The negotiations took place from May 29 to June 2, 2023 at the United Nations Educational, Scientific and Cultural Organization (UNESCO) Headquarters in Paris, France.

“We are excited to continue to enhance the capacity of INDA’s government affairs department to better serve the industry on a global scale,” said Fisher. “We look forward to working with the UNEP to provide technical input regarding ongoing plastics treaty issues specific to the nonwovens industry, and engaging with other UN processes with our new status as an accredited stakeholder.”

Kentucky-based WPT to Start-Up PLA Fabric Production

Kentucky, USA based WPT Nonwovens is to begin the production of PLA-based nonwoven fabrics for the filtration market as it looks to confirm its role as a trusted supplier of Berry Amendment-compliant products.

In February 2023, WPT announced the installation of a new thermobonding line from Trützschler Nonwovens which also included input from the machine builder’s partnership with Schott & Meissner. The high-capacity line includes the T-Blend fiber preparation system, two TWF-NC roller cards and Schott & Meissner’s high-speed Speedliner belt oven.

The line will now be used to make PLA-based nonwovens targeted at the filtration market. Made from polylactic acid, PLA fibres are a biodegradable polymer derived from renewable resources such as cornstarch or sugarcane. Also known as PLA man-made fibres, PLA fibres are synthetic fibres made from polylactic acid material.

WPT Nonwovens Corporation is a Beaver Dam, Kentucky-based, 3rd generation family-owned, nonwovens manufacturer. It began operating in 2008 and has quickly become a trusted supplier of spunbonded, needlepunched, wetlaid and carded nonwovens. As well as being a specialist in filtration media, it also supplies nonwoven fabrics for use in the medical, hygiene and industrial sectors, operating three production facilities, six nonwoven lines and five medical products converting lines.

Freudenberg Introduces the New Cotton-Like Interlinings

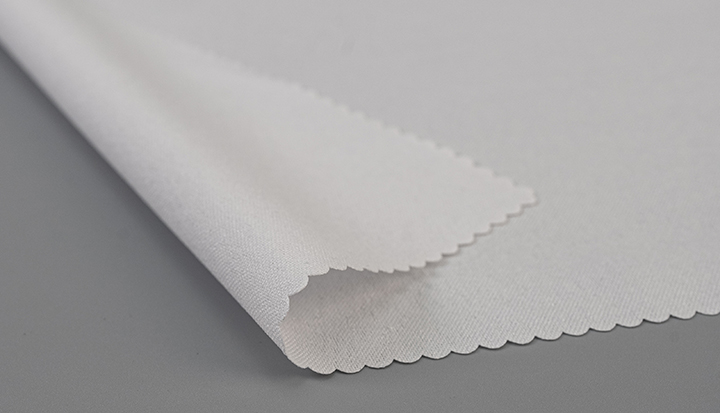

Freudenberg Performance Materials Apparel announced the 37xx PES Series – a revolutionary range of interlinings that offer the classic feel of cotton combined with the modern features of enhanced durability, increased yields, and low-temperature fusing. With a 100% PES base and special finish, these OEKO-TEX® STANDARD 100 Class I certified products open new possibilities for the business and smart casual segments. The 37xx PES Series is available for order and supplied from Asia.

The 37xx PES Series of cotton-like interlinings couples the feel of cotton you know and love with superior qualities and greater consumer safety. Crafted from a 100% PES base with a special finish, these new interlinings boast enhanced durability and better resilience and recovery over traditional cotton interlinings. The 37xx PES Series interlinings offer the added advantages of no visible impurities or foreign fibers, along with low temperature fusing, reducing the risk of yellowing in the finished product. Compared with cotton interlinings, the 37xx PES Series also offers increased yields of up to 150 cm in width and are more cost effective than traditional cotton interlinings, allowing for easier and more efficient manufacturing.

Apart from the material qualities, the 37xx PES Series offers unmatched consumer safety. Produced at its Nantong, China factory, Freudenberg ensures optimal quality control of the 37xx Series. Furthermore, the interlinings are OEKO-TEX® STANDARD 100 Class I certified, making them safe for even the most sensitive skin types, including for babies.

ITMA 23 – Great Exhibition Platform for DiloGroup

DiloGroup reported heavy traffic at its stand at ITMA 23, where the company demonstrated its line of MicroPunch technology. The MicroPunch features had been promoted in advance at INDEX to make interested parties acquainted with the features of high-speed lightweight needling.

Visitors confirmed that the current commercial and environmental issues concerning sustainability, critical energy supplies at increasing prices, shrinking water reserves as well as the outlook for fiber material savings had their utmost attention. These concerns find an answer in the field of lightweight nonwovens production through Dilo’s brand new MicroPunch production technology which will become relevant when investments take place for nonwoven production in a weight range between 30 up to more than 100 g/sqm. MicroPunch offers a tremendous savings potential for electrical energy and energy from gas heating as no water is consumed. Furthermore, there is no fiber loss associated with this production technology since trimmed material can easily be recycled within the process.

The Dilo team installing this complex line within 10 to 12 days including commissioning demonstrated its capabilities under high time pressure. It gave an example to all involved with their efficiency, coordination and professional attitude. This resulted in a great performance and added to an excellent atmosphere during these days together with our range of customers and interested parties.

Andritz AG acquired 100% stake in Dan-Web Machinery A/S

ANDRITZ has signed an agreement with Dan-Web Machinery A/S based in Galten, Denmark, to acquire 100% of its shares. Dan-Web is a leading supplier of a wide range of technologies for the production of airlaid nonwovens.

Dan-Web engineers, designs and builds customized machines and turnkey plants to produce airlaid nonwovens for baby diapers, fem care, incontinence products, wipes, and other applications. With 50 employees at the facility in Galten, the company has been a successful provider of equipment and services to the airlaid industry for almost 50 years.

With this acquisition, ANDRITZ Nonwoven is adding competence in airlaid technology to its comprehensive product portfolio.

Said Andreas Lukas, Head of ANDRITZ Nonwoven: “After more than two decades of successful collaboration, we now have decided to move closer together, which allows both of us to further develop certain processes much faster.”

Dan-Web’s product range also enables ANDRITZ to participate in the drylaid cellulose process for the production of environmentally friendly packaging and single-use products. Dan-Web is a leading supplier of hammer mills and forming head technologies for these pulp-based applications, which fits well with ANDRITZ’s expertise in pulp technologies.

Three Finalists Announced for the 2023 World of Wipes Innovation Award®

INDA, the Association of the Nonwoven Fabrics Industry, announced the three finalists for the World of Wipes Innovation Award®. The Award will be presented at the 17th annual World of Wipes® (WOW) International Conference, July 17-20, at the Atlanta Marriott Marquis in Atlanta, Georgia.

The three products vying for this Award are a cleaning and disinfecting device from 2XL Corporation, a wipe utilizing biotransformation technology from Avgol Nonwovens, and a reusable towel dispensing system from Yowel.

The winner will be announced on July 20th at 11 am. The three companies competing for the Award are:

Windup by 2XL Corporation

Meet the Windup: a groundbreaking new device that can clean and disinfect your home using a self-advancing microfiber roll that you never have to touch. Just one roll will clean your kitchen over 50 times. An innovative one-touch revolving roll and a versatile spray system that allows use of your favorite floor cleaner or our specially formulated disinfecting solution. No more stopping to change expensive pads or change filthy water. Get wound up for Windup.

Nonwoven wipe using biotransformation technology by Avgol Nonwovens

This innovative spunlace wipe utilized advanced biotransformation technology developed jointly by Indorama Ventures and Polymateria. Meeting the BSI PAS 9017 specification, this wipe in the event it becomes fugitive, and exposed to heat, sunlight, air and moisture will transform into a harmless, bioavailable wax at its end-of-life, eliminating microplastic pollution. Compatible with mechanical recycling and combatting ‘fugitive’ waste, this wipe represents a significant leap towards eco-friendly, sustainable nonwoven hygiene products.

The Yowel™ System by Yowel

Ready to help the earth and save money…every day? Yowel is a patented system for dispensing reusable towels. Instead of a roll of paper towels, place a Yowel full of reusable towels into your paper towel holder – or choose the countertop model, and you’re immediately reducing your paper towel consumption. The Yowel System has 40 reusable towels and a mesh bag for used towels. Save money and help Mother Nature.

INDA’s Technical Advisory Board selected the finalists based on the creativity, uniqueness, and technical sophistication employed in finding novel ways to expand the utilization of nonwovens. Categories considered for the award were wipes related raw materials, roll goods, converting, packaging, active ingredients, binders, additives, and end-use products.

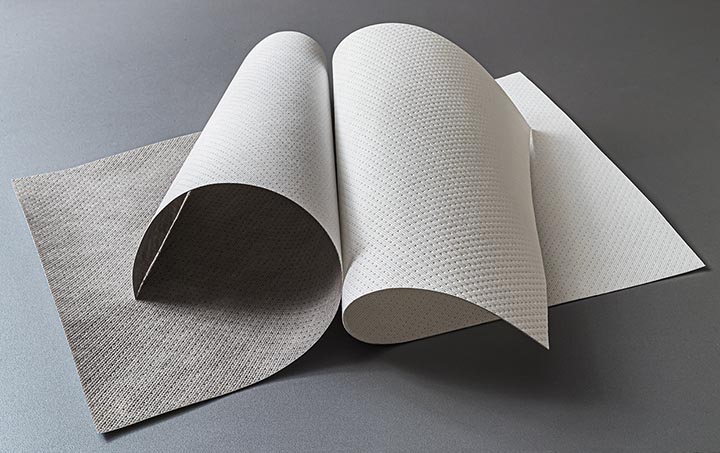

Freudenberg Launches Evolon Ultra Smooth

Freudenberg Performance Materials has launched its latest innovation to serve the specific packaging needs of technical industries. When converted into reusable textile containers, Evolon Ultra Smooth provides premium surface protection and enhanced mechanical properties. Additionally, a 100% European, condensed supply chain brings logistics benefits.

Evolon Ultra Smooth fabrics are extremely low-linting, strong and hard-wearing. The new materials are designed for industrial parts and components which require low friction, sliding behavior during the part packing and handling procedures. Furthermore, they are durably hydrophobic and available in different weights. The reusable textile containers made of Evolon Ultra Smooth can be used in various industries to pack and transport even very heavy and sensitive parts without damage.

The Evolon Ultra Smooth materials have a point-sealed patterned white surface which is very different from the standard Evolon packaging textiles and which makes them easily identifiable.

ANDRITZ Introduces New Spunlace Pilot Line for Natural and Recycled Fibers

International technology group ANDRITZ has installed a new spunlace pilot line at its center of competence in Montbonnot, France. It allows customers and partners to conduct trials for producing nonwovens from recycled and/or natural fibers such as hemp, flax, and cotton.

The new pilot line features optimized web forming and entanglement for smooth processing of sensitive and irregular fibers. The innovative card set-up is designed to protect and maintain the quality of the fibers while achieving outstanding productivity rates.

Another special feature of this pilot line is the integrated ANDRITZ Metris digitalization system. It allows the operators to collect and analyze all useful data about the line’s capacity and performance. This is a perfect tool for optimizing costs, saving time and predicting maintenance.

With the new line, the ANDRITZ Nonwoven team now operates two spunlace pilot lines at the Montbonnot technical center. The first line has optimized processes, for instance Wetlace™, for processing various synthetic and man-made fibers. ANDRITZ process experts ensure that advanced technology and know-how are available under one roof at Montbonnot.

TÜV Rheinland and BluWin to Sign MOU

As consumer demand for environmentally friendly products continues to grow, the textiles industry faces the imperative of adopting sustainability practices throughout the supply chain. To address this challenge and drive change, TÜV Rheinland and BluWin will enter a memorandum of understanding (MoU) to cooperate and bring together their respective strengths and expertise. TÜV Rheinland and BluWin will collaborate on awareness campaigns and industry events to promote more sustainable practices and foster knowledge-sharing among stakeholders.

Through this partnership, TÜV Rheinland, with its extensive experience in quality assurance, certification as well as verifications, will work closely with BluWin, a high-impact climate solution provider that offers a suite of expert solutions to identify and reduce the adverse effects of the fashion, textile, and footwear industries.

“We are delighted to formalize our partnership with BluWin through this MoU. Together, we aim to set new benchmarks for sustainability practices, creating a more responsible and eco-conscious future for the sector,” says Jia Liu, Global Sustainability Director for the Systems Business Stream of TÜV Rheinland. “This collaboration represents a significant step forward to broaden our service offerings for the textile industry: We are combining the vast knowledge of TÜV Rheinland in environmental, social and governance topics with BluWin’s expertise in textile supply chain chemicals management and process efficiency improvement. By working closely with brands and retailers and their value partners, we will accelerate the industry transformation towards more circular business practices.”

Omar Orrego, General Manager for BluWin said, “We are delighted to collaborate with TÜV Rheinland to advance environmental standards within the textiles and apparel industry. BluWin’s expert services will benefit brands and retailers, manufacturers, and other stakeholders through adopting sustainable practices, and installing process efficiency improvement as we combat environmental challenges ahead.”

Celliant With Repreve Wins Third Consecutive Award

The innovative fiber Celliant with Repreve has been awarded a Top 5 Selection in the Accelerated Eco category of the Spring/Summer ISPO Textrends 2025 Awards.

This is the highest honor Hologenix has ever received in these awards and the company’s first time in the Accelerated Eco category, where products are recognized for setting a new standard in terms of sustainability.

“This third accolade for Celliant with Repreve makes it our most award-winning carrier to date,” said Seth Casden, co-founder and CEO of Hologenix, based in Pacific Palisades, California. “Celliant with Repreve helps brands create offerings that are better for us and better for the earth.”

Celliant wit Repreve was introduced by Hologenix and Unifi.

Coloreel Milestone: 100th Patent

Coloreel has obtained its 100th patent, adding to its already substantial portfolio of worldwide patents for its innovative digital thread dyeing technology.

Coloreel’s technology allows any embroidery machine to instantly customize thread color during production. Paired with Coloreel, embroidery machines can access millions of precise colors in real time.

The company has in total 14 patent families which are active in 45 key countries. This comprehensive range of patents currently in use covering all essential aspects of Coloreel’s technology and products. The patents cover the current embroidery application, as well as potential future business areas like industrial sewing, knitting, and more.

Indorama Ventures, Carbios to Build PET Biorecycling Plant in France

Indorama Ventures Public Company Limited (IVL), a global sustainable chemical producer, and Carbios, a biotech company developing and industrializing biological solutions to reinvent the lifecycle of plastic and textiles, announced the signing of a non-binding Memorandum of Understanding (MOU) to form a Joint Venture for the construction of the world’s first PET biorecycling plant in France.

Based on and subject to the comprehensive terms set out in the MOU, Indorama Ventures plans to raise about €110 million for the Joint Venture in equity and non-convertible loan financing, pending final engineering documentation and final economic feasibility studies. Both parties have acknowledged their mutual support for the implementation of the project and their intent to finalize contract documentation before end 2023.

Subject to the successful performance of this first plant in France, Indorama Ventures confirms its intention to potentially expand the technology to other PET sites for future developments.

Under the agreement, Carbios, which filed for plant permitting in December 2022, should acquire 13ha land from Indorama Ventures’ existing PET plant at Longlaville and expects to be granted permits by Q3 2023, allowing start of construction by end of 2023 and targeted commissioning in 2025. The land surface offers the possibility to double capacity. Pursuant to this MOU, Indorama Ventures shall ensure 100% of output repolymerization and both partners shall collaborate to secure feedstock supply.

FUZE Biotech Becomes FUZE Technologies

FUZE Biotech is changing their name to FUZE Technologies and launching a new and more comprehensive website to better complement their ever-growing suite of products and services.

With roots in biotech, FUZE Technologies is growing steadily into new markets, including outdoor, hospitality, fitness and office/workspace. The new name will complement the brand’s growing list of clean solutions for antibacterial, cooling and fast drying performance.

Stäubli Group Appoints New CFO

Stäubli has appointed Roger Schnüriger as its new Group Chief Financial Officer (CFO) and member of the Group Executive Committee. He assumed his new role June 1, 2023.

With Schnüriger, Stäubli is recruiting an experienced manager, who has a strong track record in successfully transforming and developing global finance functions for industrial companies. The new appointment therefore perfectly matches Stäubli’s current business strategy for strong international growth, which the Group intends to maintain in the period ahead.

Stäubli is a major player in the textile machinery and robotics sector.