How fiber producers are exploring all options for sustainable gains.

Many new innovations for the production of nonwoven fabrics are emerging in the marketplace – the inevitable response to sustainable goals driven by global demands for environmental, social, and corporate governance (ESG) on all industry. For fiber, this includes one idea on the process of “biotransformation,” which is being commercialized by companies within the Indorama Ventures (IVL) group. This and others were presented during the 61st Dornbirn Global Fiber Conference (Dornbirn-GFC).

Around 50% of the fibers going into the approximately 470 billion baby diapers that are consumed each year are produced by IVL companies and the considerable post-consumer waste these products generate is estimated to be in the region of 30 million tons each year – all of which is either incinerated or sent to landfill.

This equates to 1.5 billion diapers that are disposed of globally on a daily basis – 18,000 each second – and this waste is not currently in a fit state to be recycled by simple recovery of its constituent parts, although some technologies are emerging to do this on a limited scale.

Even the average scrap rate of 2.5% generated in diaper production – long before reaching the retail shelves – is considerable, equating to 30,000 diapers being discarded every minute. As such, it represents a significant and potentially addressable part of the overall plastic waste problem.

Collaboration

As a global leader in PET polymer recycling and with a commitment to the circular economy, IVL currently has 14 dedicated R&D centers worldwide and is involved in over 100 collaborative projects – many with emerging new companies – to which it can contribute both extensive know-how and the ability to scale.

One of the most promising is the biotransformation process being developed with Polymateria, a spin-out from Imperial College London.

At Dornbirn 2022, Søren T. Klint, R&D director for FiberVisions (which has been an IVL company since 2012), described the process as the world’s first biodegradation technology capable of delivering full biological decomposition of polypropylene (PP) and polyethylene (PE) staple fibers and nonwovens.

The advanced catalytic system transforms PP and PE materials into a bioavailable wax which naturally-occurring microorganisms can easily assimilate. Unlike oxo-degradation, no microplastics or toxic substances are left behind after the degradation stage and the time-controlled process allows optimal use phase and recycling recovery (if a recycling option is available).

The process has been tested and certified to the BSI PAS 9017 international biodegradability standard underpinned by EN, ASTM and ISO standards and has been accredited by an independent third party, with lab data cross-checked against real world conditions.

In the storage and use phase of the product’s life – typically between six and 24 months – the technology is inactive, and the packaging behaves the same as its non-degradable conventional counterparts.

Bacteria and Fungi

If leaked into an open-air land-based environment, prolonged exposure to various environmental stimuli will trigger a rapid chemical transformation to wax within three to five months. The bioavailable wax is biologically transformed through mineralization by naturally occurring bacteria and fungi in soil. Under mesophilic/ambient temperature conditions it is transformed within twelve months.

“The key chemical distinction between biotransformation and previous technologies is the ability to promote different chemical reactions upon the polymer structure simultaneously,” Klint said. “Polymateria’s masterbatch technology goes far beyond oxidation and is a combination of C-C cleavage, photolysis, oxidation and hydrolysis. Our individually formulated pre-biotic substrate acts as an initial food-source for microbes to help boost the biodegradation in the early stages of decay.”

Selected biotransformative fibers and spunlaid nonwovens are now being made available by IVL companies.

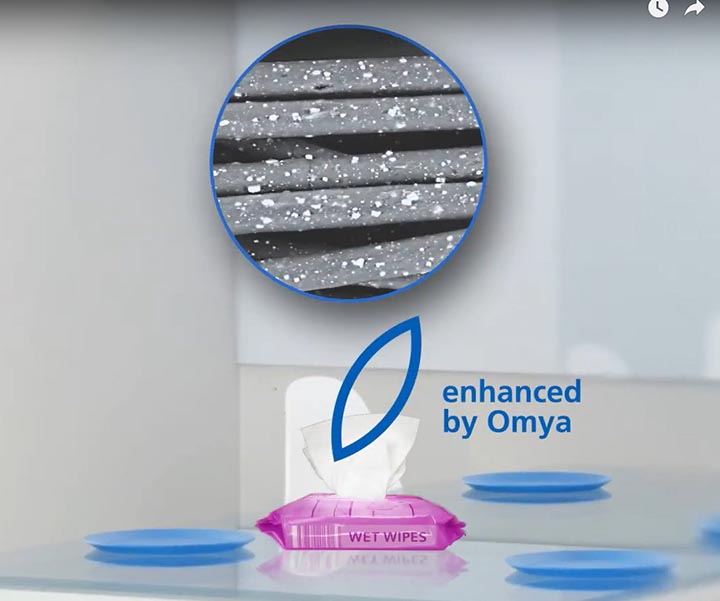

Calcium carbonate is a sustainable and renewable raw material for addressing environmental pressures.

Polyolefins

Beaulieu International Group (BIG) and IFG Group are both European polyolefin fiber producers who have recently added new pilot lines equipped for R&D projects focused on the development of sustainable new products.

BIG has three plants with an overall capacity of an annual 155,000 tons in Belgium and Italy and is a global supplier of polyolefin and bicomponent polyester/polyolefin fibers in staple, shortcut round and trilobal formats, from 1.3 to 500 dtex.

In Dornbirn, Jerico Biagiotti, the company’s product development manager for hygiene, outlined the benefits of Myralux bicomponent fibers which combine a trilobal shaped core with a uniform sheath in their construction. This enables a higher opacity to be obtained in nonwovens due to a relevant increase of the equivalent fiber diameter at the same dtex.

As a consequence, less light can pass through the nonwoven composed of these large-dimension fiber lobes and the addition of opacity additives such as TiO2 in the Meralux fibers can be significantly reduced compared to round fibers.

The fibers also create higher bulk and which in more open nonwoven structures allows for improved liquid management. In diaper topsheets, for example, this results in improved strike-through and rewet values and in acquisition and distribution layers (ADLs) enhances capillarity behavior for better wicking.

Alternatives

International Fibres Group (IFG) has plants in Austria, Belgium, the UK and the USA, with an annual turnover of around €150 million and has just opened a new fiber research center housing its latest SF1000 pilot semi-industrial melt spinning line.

It will allow the company to constantly test and evaluate new and emerging polymer types which can be developed and engineered specifically to meet the bespoke environmental and performance challenges of customers at the IFG Asota site in Linz, Austria.

The aim, explained IFG Asota’s head of R&D Andreas Weinberger, is to find new and sustainable alternatives to traditional fossil-based products.

“The IFG R&D team is keen for existing and new customers to make contact and visit the center,” Weinberger said. “Approaches for collaborative research projects are welcomed, especially by those with sustainable alternatives to fossil-based polymers and additives to test and develop. Together with our suppliers, customers and development partners we work on sustainable fiber solutions for the future, including biobased, biodegradable and recycled materials.”

A new lab testing service will provide testing for raw materials, denier testing, measurement of spin oil content, thermal shrinkage and UV testing and more.

Calcium Carbonate

IFG has also partnered with Omya, a leading global producer of calcium carbonate, to explore new fiber product performance, characteristics and applications which will incorporate Omyafiber, a specially developed calcium carbonate for fiber and nonwoven applications.

The collaboration commenced with successful trials of the incorporation of Omyafiber masterbatches into polypropylene and PLA staple fibers, and further polymer types are under consideration to be tested on the pilot line.

Calcium carbonate is a sustainable and renewable raw material addressing some of the environmental pressures on the fibers industry. Its carbon footprint is approximately 300kg CO2 per ton of calcium carbonate and it can be used in recycled materials and is also recyclable itself.

When Omyafiber is combined with staple fibers, the research and development teams have already discovered improved haptics, opacity and whiteness. It can replace the use of titanium dioxide which has a significantly higher carbon footprint.

Due to the high thermal conductivity properties of Omyafiber in the polymer matrix, it allows for products to be created that have lower sealing/bonding temperatures and it is also approved for use in applications that will come into contact with food.

In addition, Omyafiber does not cause skin sensitivity and is Oeko-Tex approved for use in apparel.

Cellulosics

On the cellulosics front, Lenzing has so far invested €26 million in the development of a pilot line in Austria for its web technology process, which enables the single-step pulp fiber extrusion and hydroentanglement of 100% cellulosic nonwovens.

Lenzing envisages web technology to be the answer to generating the lowest CO2 footprint cellulosic nonwovens available through its integration with localized wipes converting operations.

“The advantages of a consolidated wipes supply chain are manifold and bring benefits for the environment and the customer,” explained Lenzing product developer for the project, Katharina Gregorich. “During the process it enables material wetting and drying steps to be eliminated and closed process loops to be established for the rapid adjustment of fabric properties. For the end-customer, full traceability of the single-source products is guaranteed with the opportunity to save on packaging, transportation, and material handling steps.

Key to the Lenzing web process is the design and rheology of the spinnerets, along with coagulation during extrusion prior to web formation, followed by washing, hydroentanglement and drying.

Patents

Lenzing has so far filed 40 patents in relation to the process, which is based on Lyocell fiber and roll-goods production, and trials have been carried out on three commercial wipes converting machines to confirm its viability. The range of substrates produced is characterized by fast wicking, the homogeneous lotion distribution in a stack of wipes and good cleaning properties.

Flexibility in production allows products to be produced, for example, with a soft surface for next-to-skin operations and a coarse side for dirt removal and pickup. The binder and finish-free fabrics have a very even and homogonous surface area and their abrasion resistance can be improved through perforation. The substrates can also be hydro embossed.

Knitted Structures

Work at Kelheim Fibres in Germany is meanwhile proposing the potential replacement of nonwovens in certain absorbent hygiene products in the development of new period panties based on knitted structures.

The company’s new business development project leader Natalie Wunder explained that alternatives to single-use period products still often contain up to 90% non-biodegradable components, with synthetic fibers like polyurethane in their backsheet which during washing can cause microplastic emissions.

To maintain performance, the products are often also only washable at 40°C and to compensate for the hygienic disadvantage, biocides are frequently used.

Kelheim’s concept for sustainable period panties that can be washed at higher temperatures is based on a four-layer knitted structure, with the topsheet produced with perforated tucks based on the company’s Danufil standard viscose fibers which have a cloud-shaped cross section.

For the acquisition and distribution layer (ADL) a double piqué knitted structure is proposed, incorporating Galaxy fibers with trilobal cross-sections to provide effective liquid distribution.

The absorbent core is a pile-loop knit for improved absorption including Bramante hollow fibers which are ideal for liquid storage, even under pressure. (See IFJ Issue 5, page 44, for the full story.)