After many years of talking amongst itself, the circular economy and sustainability remain key challenges for the fiber industry.

After two years in the virtual space, the 61st Dornbirn Global Fiber Congress (GFC) bounced back with an in-person event in the small but attractive city of Dornbirn in Vorarlberg – a mountainous state in western Austria, bordered by Germany, Liechtenstein, and Switzerland.

Although overall numbers were down on previous live events, congress organizer Friedrich Weninger said he was “overwhelmed” with this year’s participation, all things considered.

The annual conference, traditionally held in mid-September, attracted more than 550 delegates from 32 countries, mostly from Europe (83% of registrations), with over 240 companies and institutes represented. There were, not surprisingly, few delegates from Asia this year.

Keynote speakers on the first day of the congress addressed the perennial issue of sustainability, which is increasingly under scrutiny with growing pressure from regulators and stakeholders, as well as consumers.

Slow Implementation

Analysis by Tecnon Orbichem suggests that the fast-fashion market has been woefully slow to implement sustainable practices within its supply chains. Circularity in the sector is similarly bleak, with no more than 1% of textiles currently being reused or recycled, with most clothing either incinerated or going to landfill. An estimated 92 million tonnes of textile waste are generated every year – the equivalent of one garbage truck every second.

Opening the Dornbirn congress, Dr Thomas Riegler, partner at PricewaterhouseCoopers Austria, said: “All negative impact is caused by humans and our unsustainable economy. We have been advancing human development by using resources faster than our planet can renew them.”

At the same time the environmental, social and governance (ESG) framework and rating landscape is evolving fast, said Riegler. “But is sustainability an overused term that is gradually losing its meaning and becoming blunt? How is it that companies and governments with pledges on climate change are suddenly claiming to be sustainable in their reporting and marketing, yet we have seen the highest increases in emissions?”

Fossil Fuel Subsidies Double

“Climate pledges and global ambitions on climate change being communicated by governments and large corporates look great on paper, but we are subsidizing global fossil fuels more than ever,” Riegler continued. “The big five oil companies are still investing 12% of their capital expenditure in fossil fuels – not renewables or other low-carbon resources.”

Riegler pointed out that in May 2022, the amount of carbon dioxide (CO2) in the earth’s atmosphere hit a record level of 421 ppm. In addition, Europe had its hottest summer ever – and hottest August – and there were heatwaves across central and eastern China in all three summer months.

He argued that, with no common understanding and definition of sustainability, current ESG reporting is a broken system that needs urgent repair. “The economy, society and environment are all interlinked. We must think sustainability strategically and take a whole-systems perspective.

“Most of the innovations we need are already here. We just have to execute them, to work and implement these technologies, to make a real-world impact, not just reporting them.”

Decline in Consumer Confidence

Against the backdrop of the current high cost of energy and rising inflation, Robert van de Kerkhof, president of the Austrian Fibers Institute and president of CIRFS, the European Man-Made Fibres Association, said it was a great achievement to continue the Dornbirn spirit after a two-year physical absence.

“But around the world, consumer confidence is at a record low level, while in China there is uncertainty with the ongoing pandemic,” said van de Kerkhof, chief commercial officer of wood-based cellulosic fibers producer Lenzing.

“Although we have been talking about CO2 improvements for a long time with science-based targets, CO2 levels are now increasing post-COVID. And we are starting to switch back to non-sustainable alternatives because we need to keep production going, which will mean a huge price on CO2 emissions – we are still heavily dependent on fossil fuels.

“And as a consequence of our over-consumption, we are using twice as many garments as we were 10 years ago, but wearing them half as much, with most ending up as waste, which could be a raw material in the circular economy.”

Renewable Fiber Gap

Although three years of growth has been lost through the pandemic, the fiber industry is one of the few sectors that is showing consistent year-on-year growth, increasing by 3 to 3.5% a year on average, driven by the rising global population and increasing disposable income, especially for the growing middle class.

But while demand is increasing, the industry is facing a dramatic renewable fiber gap. Polyester production in 2020 was double that of 2000, and in 2030 synthetic fibers will exceed 75% of total global fiber production. “We are consuming more clothing per capita than ever,” van de Kerkhof told the audience.

The fiber market is expected to grow by another 45 million tonnes by 2030 compared with 2020. This growth will be mainly due to increasing demand for synthetic fibers, which still largely rely on oil. “This is not going to improve our industry and we will have failed if this prediction comes true,” he said.

“So let us recycle polyester and other fibers with closed-loop production. There are a lot of initiatives taking place in both chemical and mechanical recycling. But this will only account for about 20%, or seven million tonnes, of the total increase in synthetic fiber demand to 2030, which leaves more than 30 million tonnes of oil-based production.

“Do we need this additional growth? Can we not reuse, buy less and wear longer, keeping carbon in the loop? Circularity is a must, and this needs to be driven through innovation in products, processes and business models.

“We also need to bring standardization and transparency into terms like ‘eco’ or ‘bio’ to the consumer to gain their trust and avoid the problem of greenwashing, making sure the products we are innovating are having an impact.”

Impact of Resources

Uday Gill, chief strategy officer, Indorama Ventures, argued that circularity alone will not be enough; it will just keep the cycle going. “We need to reduce the impact of resources and energy to continuously improve,” he said.

Gill noted that the global textile industry has gravitated towards low-labor cost countries for production, where there is lower regulation: “However, carbon emissions do not respect national boundaries and impact everyone – not just in China. And ultimately, this means short-lived economic prosperity for the low-cost countries, which can have long-term environmental repercussions.”

He said the textile industry is responsible for 10% of global carbon emissions, 20% of global water pollution and 35% of microplastics in the world’s oceans, as well as contributing to 2% of global gross domestic product and employing nearly 12% of the global workforce.

Meanwhile, 30% of clothing shipped from Asia to North America is never sold and is sent to landfill or incinerated, which means a loss of around 100 million tonnes of fiber a year at present and 116 million tonnes a year by 2030.

In addition, manufacturing of textiles, including fiber, yarn and fabric production as well as garment making, accounts for 75% of the environmental impact of fast fashion, with the remaining 25% due to consumption/end of life.

MARK the CALENDAR for 2023

The 62nd Dornbirn GFC is scheduled to take place from September 13–15, 2023 in Dornbirn, Austria, which will include the 3rd Innovation Days, where start-ups and young innovative companies are invited to present their company and products. The deadline for this, and the traditional call for papers for the congress, is December 31, 2022.

For more information contact: Austrian Fibers Institute, Tel: +43 1 319 290941,

Email: office@dornbirn-gfc.com, www.dornbirn-gfc.com

Brand Commitments

“All the major brands have made commitments to used recycled polyester and other fibers, such as sustainable cotton and/or ‘responsibly sourced’ raw materials. A lot of visible commitment [to sustainability] is there, but where are the disclosures?” Gill said.

With demand from the packaging industry for recycled polyethylene terephthalate (PET) bottles growing, there will be less availability for bottle-to-textile recycled fibers. Meanwhile, like-to-like textile recycling has only reached around 0.5% of fiber production.

“We have to design products for next life, adopt new technologies and create new models to promote supply chains near consumption centers,” Gill stated. “We have to change and bring a new mindset to the industry.”

He explained that textile circularity in 2030 will require collaboration across all stakeholders for a unified approach to protect the environment. But this will need some agency, “one conductor of this orchestra,” to lead this cross-discipline collaboration on a global scale as an integrated approach will help in developing appropriate solutions.

“Regulation, while painful, will encourage innovation, create capacity and deploy technology for scalable solutions, particularly low-energy solutions, to promote circularity,” Gill concluded.

“To accelerate circularity and achieve our goals, we need to create end-to-end local infrastructure and smart value chains near the consumption centers for proximity sourcing based on recycled feedstock and apply appropriate technologies with a high level of automation, artificial intelligence and machine learning.”

Range of Topics

With around 100 presentations delivered across three halls of the Kulturhaus Dornbirn, the annual fiber congress covered a wide range of topics: fiber innovations; sustainability, circular economy and recycling; smart functional surface; nonwovens; and apparel and sports.

In a new development the lectures were available on demand for three weeks after the event, and for the first time there were no simultaneous German/English translations. In addition, the Dornbirn congress included the 2nd Innovation Days with 14 European start-up companies presenting their latest ideas.

Prize Winners

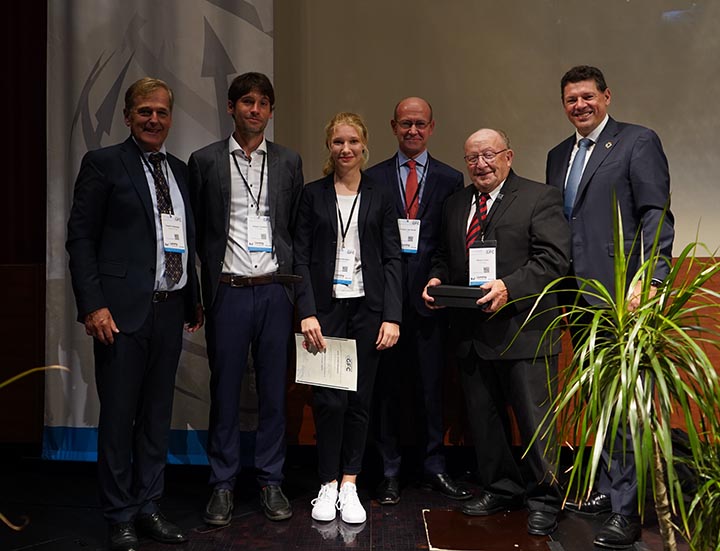

During the event, Frédéric Van Houte, director general of CIRFS, presented the Paul Schlack/Wilhelm Albrecht Prize 2022 to Robert Tonndorf of the Institute of Textile Machinery and High Performance Material Technology (ITM), Technische Universität Dresden, Germany, for his project: “Development of manufacturing technologies for the production of biomimetic fiber-based scaffolds from collagen for tissue engineering and regenerative medicine.”

The honorary prize was awarded to Leonie Reinders of DITF Denkendorf, Germany, for her project: “Development of novel oxide ceramic fibers for high-temperature applications.”

Meanwhile, a lifetime achievement award was presented to Professor Hilmar Fuchs, who is retiring after many years with the Saxon Textile Research Institute (STFI) in Chemnitz, Germany.

Women Power

At the gala dinner hosted by the Mayor of Dornbirn, Andrea Kaufmann, the Young Scientist Award sponsored by Lenzing was presented to three women, who each received €5,000 in prize money.

Chanawan Danpan and Irene Purasachit have produced a regenerative bio-based textile material called Flaux, made from flower waste, which is a nonwoven leather-like material that can be used in the fashion industry. Their Flower Matter project has resulted in research at two EU institutions (Germany and Finland) from design and management perspectives.

Petra Garajová of Fabricademy – Textile and Technology Academy, Nové Zámky, Slovakia, is a designer exploring the boundaries of material science, digital manufacturing and innovation. Her project “States of matter – wool fibers and non-traditional methods” investigated the chemical properties of wool waste, with the material research focused on the extraction of keratin and the use of sustainable chemicals.

The “Purhyphae project: textile recycling using mycelium” by Annah-Ololade Sangosanya of the Institute for Advanced Architecture of Catalonia, Barcelona, Spain, investigated ways of producing flexible mycelium materials through the biodegradation of various combinations of denim textile waste, synthetic textile waste, food waste and spent coffee grounds.