JX Nippon ANCI, headquartered in Kennesaw, Georgia, USA, with manufacturing in Roanoke, Alabama, and Dalton, Georgia, has launched the Milife range of fine-denier polyester nonwovens for filtration applications.

Milife uses a proprietary technology that results in continuous fibers like spunbond, but with a process that results in unique appearance and properties.

The Milife process produces fabrics with high orientation, low elongation, low denier fibers with both machine-direction (MD) and cross-direction (CD) fiber alignment.

Milife is available as MD only or with MD and CD strands. It is manufactured in Japan by a sister company in an ISO 9001-certified facility and is exclusively distributed by JX Nippon ANCI.

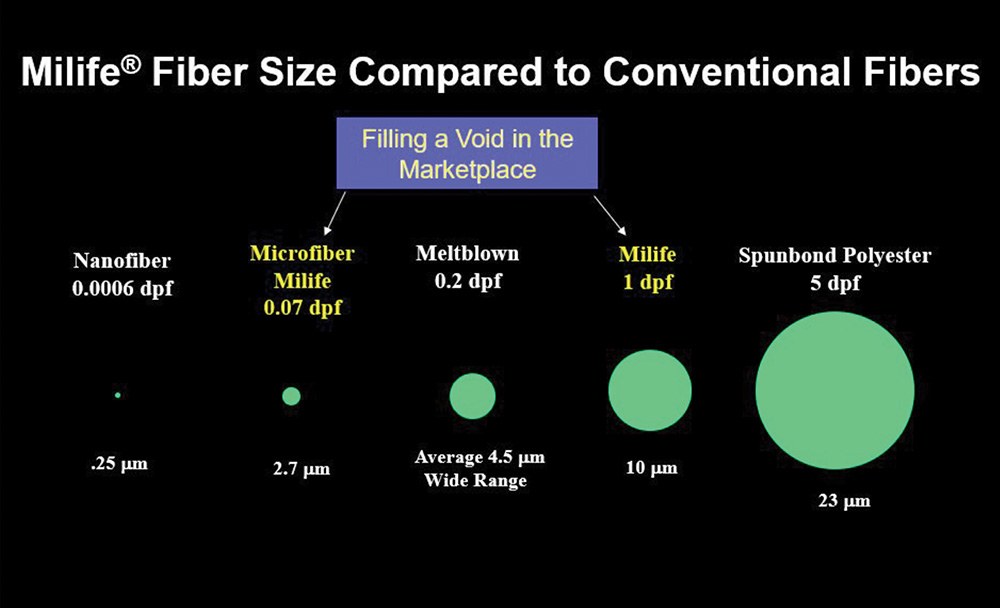

The technology allows a very fine fiber size – much smaller than spunbond. Whereas spunbond polyester has fiber diameters of 18–30 µm, Milife has fiber diameters of 10 µm (1 dpf), which is not available in a spunbond, and Microfiber Milife has fiber diameters of 2.7 µm.

This places Milife between spunbond and meltblown, with Microfiber Milife finer or equal to meltblown in terms of fiber sizes. This provides additional options for filter construction that have not been available previously.

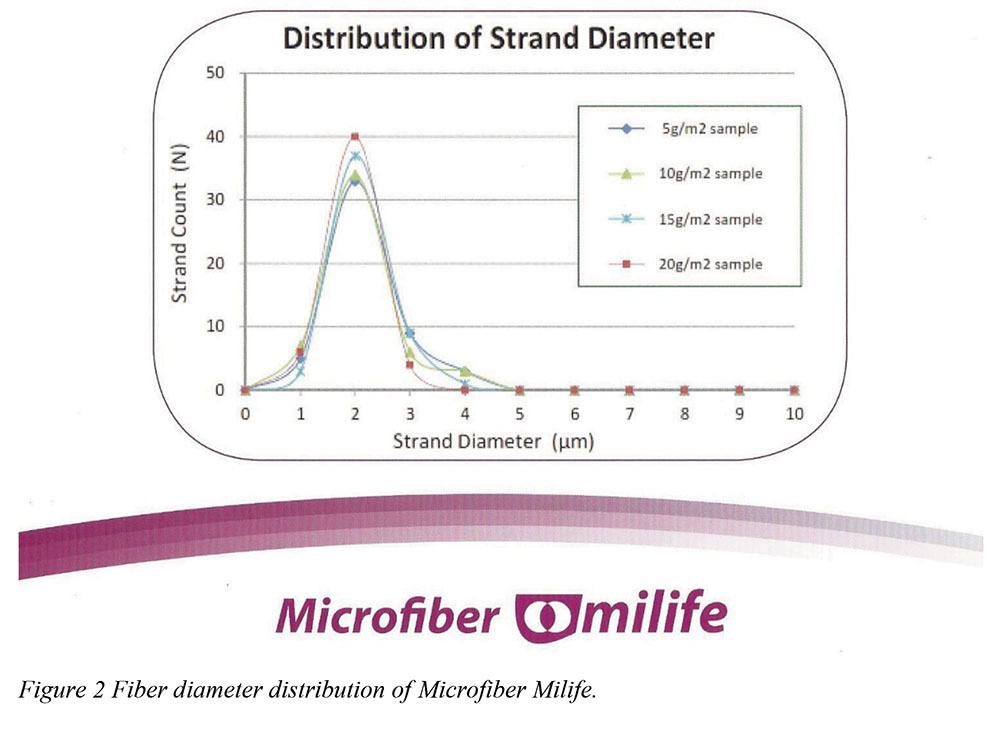

Milife and Microfiber Milife are thin products, with exceptionally narrow fiber size distribution, low elongation, dimensional stability and excellent web uniformity. Figure 2 shows the fiber diameter distribution of Microfiber Milife.

Milife and Microfiber Milife in available with weights of 5-60 g/m2. Milife Microfiber can be used as a performance layer in filtration media composites. It has the tensile strength to be unwound and fed directly as a single layer into a lamination process, including the 5 g/m2 unit weight.

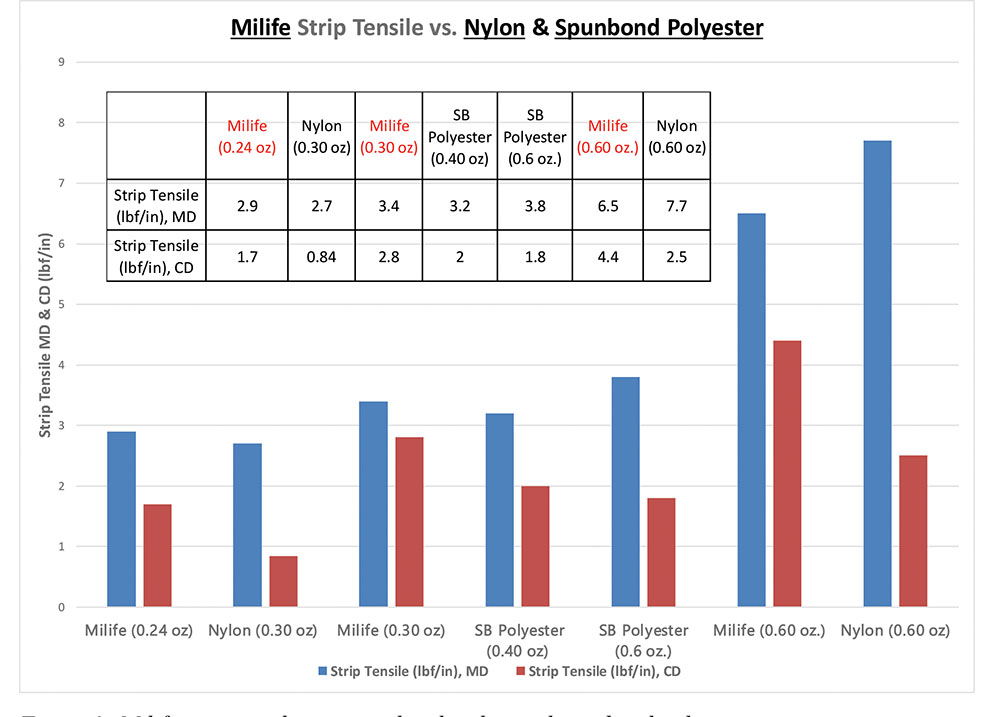

Milife compares favorably in strip tensile with polyester and nylon spunbonds as shown in Figure 3.

Milife and Microfiber Milife are currently used in luxury packaging, interior decoration, specialty tapes, medical, sound absorption and various industrial applications.

Milife can be used in filtration products as a support material, as a filter media or as a fine-denier performance component in composites.

Gabriel Cuellar, JX Nippon ANCI vice-president sales and marketing, said: “We are excited [about] the launch of Milife for filtration applications and believe Milife with its unique properties offers additional and new options to filter manufacturers.”

For more information contact:

Kyle Cook, Filtration Manager

JX Nippon ANCI Inc

Tel: +1-404-891-1320

Email: kyle.cook@jxanci.com

Website: www.jxanci.com