By Synthetic fibers have taken a bashing in recent months, with numerous press reports suggesting much of the world’s drinking water is contaminated with plastic particles and that washing synthetic clothing could damage marine health.

With such headlines as: “Plastic fibres found in tap water around the world, study reveals”, “If you’re drinking tap water, you’re consuming plastic pollutants”, “Just how much plastic is ending up in our shellfish?”, “Plastic being ingested by fish and humans” and “Is your fleece killing marine life?”, the synthetic fiber industry has much to ponder.

Some research suggests that microplastic particles released by synthetic fiber fabrics could harm marine life when they enter rivers and oceans.

A recent study showed that a single wash in a domestic washing machine can release huge numbers of microscopic fibers into the environment.

A team at Plymouth University in the UK spent 12 months analyzing what happened when a number of synthetic materials were washed at different temperatures in domestic washing machines, using different combinations of detergents, to quantify the number of microfibers shed.

They found that acrylic fabric released around 730,000 tiny synthetic particles per wash – five times more than polyester/cotton fabric and nearly 1½ times as many as a 100% polyester fabric.

The problem potentially arises when these plastic microfibers are ingested by marine organisms, which could cause detrimental effects.

Although not conclusive, a number of studies indicate that these particles have the potential to disrupt the food chain, build up in animals’ digestive tracts, reduce the ability of some organisms to absorb energy from foods and even to change the behavior of crabs.

Meanwhile, other tests suggest that billions of people worldwide are drinking water and other food-type liquids that are contain plastic particles.

According to a report published in September in UK newspaper The Guardian, scores of tap water samples from more than a dozen countries were analyzed, with 83% of the samples contaminated with plastic fibers. Scientists have called for urgent research on the implications of this study for human health.

Dornbirn roundtable

The issue of microplastic fibers from textiles was a major talking point at September’s Man-made Fibers Congress held in Dornbirn, Austria. A highlight was the panel discussion moderated by Walter Woitsch of Syngroup Management Consulting, Austria.

With their huge sales volumes and significant use of synthetic fibers, several enlightened fashion/sportswear brands recognize that they are part of the problem.

Philipp Meister, manager sustainable materials and innovation at Adidas, Germany, said more interactions with consumers will create a huge opportunity, but stressed the need to create global awareness of the issue.

“We aim to create new ways of creating new products with reduced fiber shedding and to upscale wastewater plants to treat the problem of microplastics before they enter the water cycle,” he said.

Celine Dolan of Wellman International, Ireland, admitted that polyester is indeed contributing to the problem of marine litter, “but we want to be part of the solution.

“The challenge of recycling polyester has to be driven by consumer demand; that is, the whole process has to be economically viable. But we need the market to come to us.

“It will cost a lot of money to treat the problem of marine litter and water ingestion, but this presents a new opportunity with, for example, biodegradable polymers. Polyester is not going to go away.”

Robert van de Kerkhof, chief commercial officer of Lenzing, Austria, does not believe the fiber industry is fully aware of the problem, let alone how to prevent it from getting worse.

“For example, consumers are using more wet wipes that are being flushed. These products contain cheap synthetic fibers, but why should consumers change their behavior? The industry needs to raise awareness of this problem. And Europe has to take the lead in combatting marine litter.”

Dr. Wilhelm Rauch, managing director of Industrievereinigung Chemiefaser (IVC), the Association of the German, Austrian and Swiss Man-Made Fibres Industries, said its members are taking the problem very seriously and feel a huge degree of responsibility.

Prof. Franz Josef Radermacher of the University of Ulm, Germany, stated that the biggest problem is not microplastics – rather it is the unabated growth in the world’s population, especially in Africa, which will double its population by 2050.

“Our main issue is to improve living conditions,” he said. “Development is the most important issue for most people.

Waste management

Hugo-Maria Schally, head of the European Commission’s Sustainable Production, Products and Consumption unit, noted that there had been a high degree of publicity concerning marine litter. This had initially been on macro-litter, but this will gradually become microplastics and ultimately nanoplastics.

“We have to enlarge waste management capacities, especially in developing countries,” he said, reminding delegates that developed regions, such as the EU, also export significant amounts of waste materials.

“It is clear that there is a problem with microplastics, but we are not there just to propose policies. We need to tackle the problem at source, i.e. in the design of the product. Let us not panic about marine litter, but work with the value chain to solve the problem.”

Research shortcomings

In a review and evaluation of studies on the release of synthetic fibers from washing, IVC’s Michael Stark said many of these reports omitted detailed information about the textile products tested, have shortcomings in the design of the study, and used flawed or questionable methods.

Only the study by the Laboratory of Polymer Chemistry and Technology of the National Chemistry Institute in Ljubljana, Slovenia (Pirc et al., 2016), published in Environmental Science and Pollution Research, can be regarded as presenting reliable results of the shedding from washing and tumble drying, which was achieved from a polyester plush (polar fleece) blanket, which is regarded as a shedding-sensitive product.

The washing treatment used in this study allows a distinction between the shedding due to mechanical treatment and the release of remaining or weakened fibers from the product’s manufacture.

The loss during washing after tumble drying resulted in <40 fibers per g of plush fabric made from 1 dtex microfibers under mild washing conditions.

“However, this and other results of fiber release from any individual textile product are absolutely not suitable for any extrapolations of released fibers into sewage water,” Stark stressed. “Too many factors have an impact and textiles are too variable and complex.”

Further, the release of fibers left over from the garment manufacturing process and the shedding of fiber by any mechanical treatments should be differentiated more clearly in all future examinations.

“The shedding behavior of synthetic fabrics should be regarded as a quality criterion for which simple tests needs to be implemented,” he said.

“The forensic tape test might be suitable for that purpose, which should be compared with laundering in simulated laboratory equipment and in washing machines.”

Flushable wipes

Meanwhile, the whole microplastics/marine pollution debate could be good news for cotton and other cellulosic fibers such as viscose.

Kelheim Fibres of Germany, said part of the problem could be solved by substituting conventional wet wipes, which contain a significant proportion (e.g. 85%) of synthetic fibers, by wet wipes made with cellulose and the company’s short cut viscose fiber. Both raw materials are plant-based and therefore completely biodegradable, said the specialty viscose fiber producer of Kelheim, Germany.

Compared with conventional wipes containing polyester, wipes made of Viloft short cut fibers can be flushed and will disintegrate into small particles that do not block private or municipal sewage systems.

Viloft has since been granted the “OK biodegradable MARINE” certificate from Belgian certification body Vinçotte. The fibers were tested according to ISO standards that confirmed they naturally break down completely in marine water.

Contaminants

At the Dornbirn congress, Kelheim Fibres business manager Horst Wörner discussed the company’s contribution to the reduction of marine litter, while his colleagues, Dr. Nina Köhne and Dr. Roland Scholz, outlined further innovations.

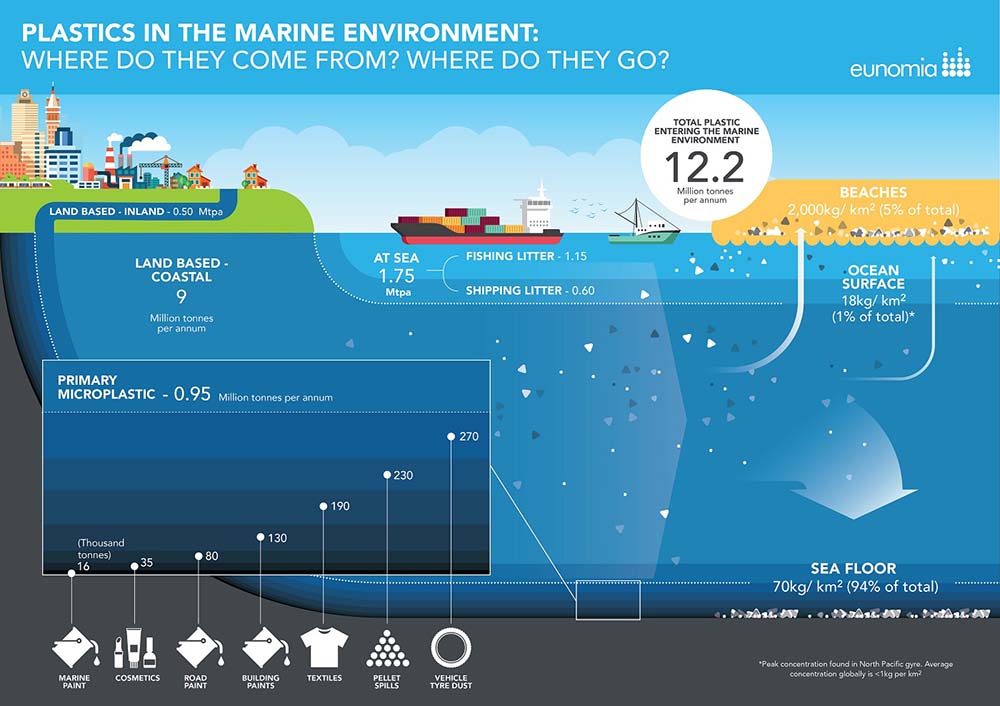

Wörner noted that 12.2 million tons of plastic enters the marine environment every year. Of the 950,000 tons/annum of primary and secondary microplastics (i.e. with a diameter of <5 mm), textiles is the third largest source with 190,000 tons, behind vehicle tire dust (270,000 tons) and pellet spills (230,000 tons).

Meanwhile, the lifetime of plastic contaminants is very long: a disposable diaper, for example, takes around 450 years to completely decompose in the marine environment, compared with 1-5 years for wool socks and 2-5 months for a cotton shirt.

“The more that non-degradable material is replaced by biodegradable components the faster this material will disappear,” said Wörner.

Wound dressing

Köhne presented the results of a joint research project with Resorba. Based on the biopolymers cellulose and collagen, the scientists created a multifunctional wound dressing that is said to be significantly superior to existing products as a result of its pH indication and gel-forming and wound healing properties.

Scholz highlighted carbon fibers that can be manufactured sustainably by using the renewable raw material cellulose in the form of viscose fibers as precursors.

By modifying the viscose fiber during its production, the course of the subsequent carbonization can be changed in specific ways, he said.

For instance, a significant increase in the yield of carbon, as well as a reduction of undesirable pyrolysis byproducts, can be achieved.

Tencel “reborn”

Dr. Christian Weilach of Lenzing introduced Refibra, which combines pulp from scraps of cotton clothing and pulp from wood, to produce “reborn” Tencel fiber.

The company teamed up with Spanish fashion retailer Inditex to identify raw materials suitable for recycling prior to garment making, collect these materials during production, and develop a logistics and supply chain.

Refibra is produced in the same process as Tencel and there is no change in fiber characteristics, said Weilach. Refibra fibers are certified according to the Recycled Claim Standard.